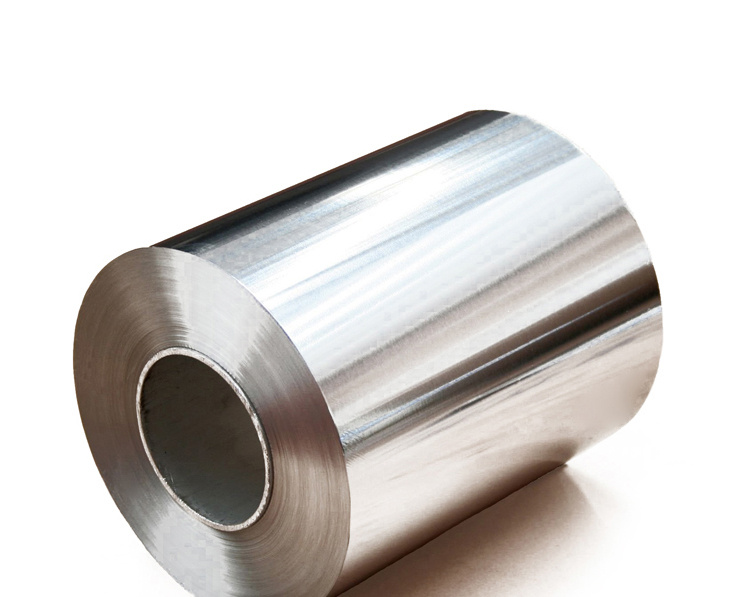

Aluminium foil (or aluminum foil in North America; often informally called tin foil) is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 4.5 micrometers (0.24 mils) are also commonly used.In the United States, foils are commonly measured in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The aluminium foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated with other materials such as plastic or paper to make them stronger and more useful.

It is widly used in packing,insulation,cooking,decoration and so on.Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe (wrongly) that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation. Increased reflectivity decreases both absorption and emission of radiation. Foil may have a non-stick coating on only one side.[10] The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

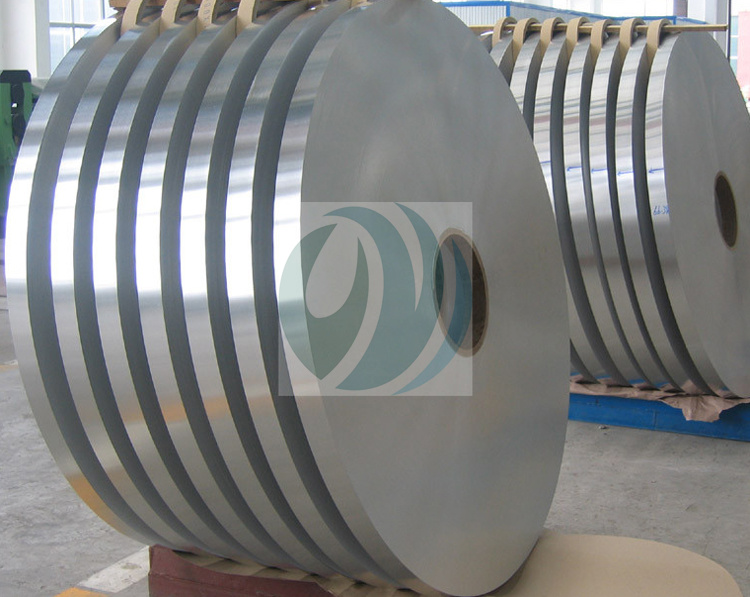

aluminium foil